Modular Work Platforms

These Modular Work Platforms can be used in hundreds of different applications and offers the best access solutions. Simply because of the variety of components that can be configured.

- Available in Aluminum or Painted Steel Construction

- Stairs and Platforms are 30 inches wide

- Slip Resistant decking

- Stair railing height of 32 inches

- Platform railing height of 42 inches

- Handrails comes with mid rails and toe boards

- Weight capacity is 50 lbs/sq ft (500-1000 lbs)

- Steps are 9 1/2″ deep with 45 degree incline angle

- Meets All OSHA and ANSI standards

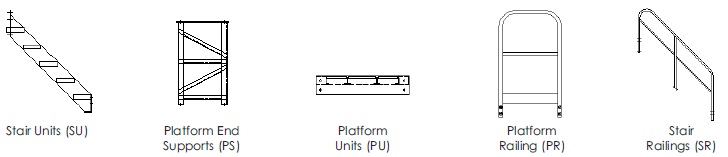

(MASU) Stair Unit 18” to 81” high

(MASU) Stair Unit 18” to 81” high

(MAEU) Platform End Support 18” to 81” high

(MAPU) Platform Unit 30”, 60”, & 120” lengths

(MAPR) Platform Railing match platform length

(MASR) Stair Railing match stair unit number

(T-ADPT) T-Adapter to attach one platform to the side of another platform

(S-ADPT) Stair Adapter to attach stair unit to platform when using only one handrail or no handrail

Modular work platforms are versatile, customizable structures designed to provide elevated access in various industrial, construction, and maintenance environments. They consist of interlocking components that can be assembled in different configurations to meet specific needs. Here are the key features and benefits of modular work platforms:

HERE ARE SOME FEATURES

1. **Customizability**:

– Components such as stairs, guardrails, ladders, and handrails can be added or removed based on the requirements.

– Configurations can be adapted to fit unique spaces or to accommodate specific tasks.

2. **Ease of Assembly**:

– Typically, these platforms are designed for quick and easy assembly without the need for specialized tools or skills.

– They can be easily disassembled, moved, and reassembled in a different location.

3. **Durability**:

– Made from robust materials such as aluminum or steel, ensuring long-lasting use and resistance to harsh conditions.

4. **Safety**:

– Incorporate safety features like non-slip surfaces, toe boards, and guardrails to protect workers from falls and injuries.

5. **Load Capacity**:

– Designed to support significant weight, making them suitable for heavy-duty applications.

HERE ARE SOME BENEFITS

1. **Versatility**:

– Suitable for various industries including manufacturing, construction, aviation, and warehousing.

– Can be used for multiple purposes such as maintenance, inspection, production tasks, and more.

2. **Cost-Effective**:

– Modular design means only purchasing the necessary components, and they can be reused and reconfigured as needs change, reducing long-term costs.

3. **Efficiency**:

– Improve workflow by providing easy access to elevated or hard-to-reach areas, reducing downtime and increasing productivity.

4. **Compliance**:

– Designed to meet industry safety standards and regulations, ensuring compliance with occupational safety requirements.

5. **Scalability**:

– As operations grow or change, additional components can be added to extend or modify the platform without the need for a complete overhaul.

EXAMPLES OF SOME APPLICATIONS

– **Industrial Maintenance**: Facilitating access to machinery and equipment for repair and upkeep.

– **Construction Sites**: Providing stable and adjustable platforms for workers to perform tasks at height.

– **Warehouse Operations**: Helping in managing high shelving and storage systems.

– **Aerospace and Aviation**: Offering specialized platforms for aircraft maintenance and inspections.

– **Assembly Lines**: Enabling workers to efficiently reach different parts of a production line.

In summary, modular work platforms are an essential tool for any industry that requires safe and efficient access to elevated workspaces, offering flexibility, safety, and cost savings through their adaptable design.